iWin®- DIGITAL GLASS

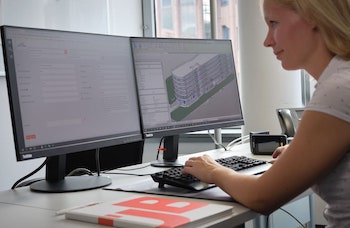

MAKING PAPERWORK A THING OF THE PAST

When will the glass you ordered arrive? Does the glass delivered match the order? And which insulating glass was used in the old facade way back when? The more complex building projects and supply chains become, the more paper is required to keep track of all the details. This approach isn’t just error-prone and time-consuming. Now, it’s completely unnecessary, too: Insulating glass using iWin® technology can be tracked in detail online from production to assembly, clearly identified even after years have passed and itemised based on all parameters, from glass structure and coating to processor and order data. Glass has never been so transparent.